Burlingame Robotics Swerve Chassis

Overview

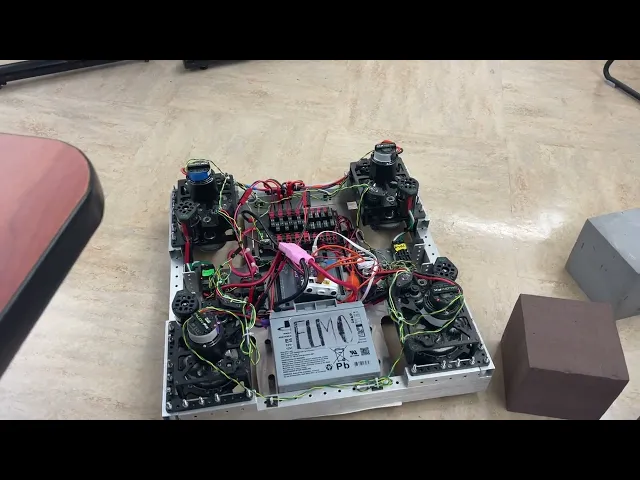

During the 2021 offseason, I was tasked with leading the design and manufacture of an experimental swerve‐drive drivetrain for the next season. Drawing inspiration from a concept I had seen online, I engineered a compact chassis in SolidWorks that fit comfortably within the 22″×22″ competition frame—significantly smaller than our previous design—and gave the robot enhanced maneuverability. I then modeled and CAM‐programmed every custom component in Fusion 360 and machined them on the team’s CNC router. In our first tests, the new drivetrain—with wheels capable of simultaneous rotation and translation—demonstrated a marked reduction in cycle times.

Categories

Robotics

FIRST Robotics Competition

Date

Jan 2021

-

Jun 2021

Swerve Drive

Burlingame Robotics Swerve Chassis

Overview

During the 2021 offseason, I was tasked with leading the design and manufacture of an experimental swerve‐drive drivetrain for the next season. Drawing inspiration from a concept I had seen online, I engineered a compact chassis in SolidWorks that fit comfortably within the 22″×22″ competition frame—significantly smaller than our previous design—and gave the robot enhanced maneuverability. I then modeled and CAM‐programmed every custom component in Fusion 360 and machined them on the team’s CNC router. In our first tests, the new drivetrain—with wheels capable of simultaneous rotation and translation—demonstrated a marked reduction in cycle times.

Categories

Robotics

FIRST Robotics Competition

Date

Jan 2021

-

Jun 2021

Swerve Drive

Burlingame Robotics Swerve Chassis

Overview

During the 2021 offseason, I was tasked with leading the design and manufacture of an experimental swerve‐drive drivetrain for the next season. Drawing inspiration from a concept I had seen online, I engineered a compact chassis in SolidWorks that fit comfortably within the 22″×22″ competition frame—significantly smaller than our previous design—and gave the robot enhanced maneuverability. I then modeled and CAM‐programmed every custom component in Fusion 360 and machined them on the team’s CNC router. In our first tests, the new drivetrain—with wheels capable of simultaneous rotation and translation—demonstrated a marked reduction in cycle times.

Categories

Robotics

FIRST Robotics Competition

Date

Jan 2021

-

Jun 2021

Swerve Drive